- Menu

Featured Case Study

The Orchard Residential Development

MagnumStone™ for Retaining Walls.

- ProductsFeatured ProductsGeotextilesGeogridsReinforced Soil SystemsBlock Retaining SystemsGabionsTurf MattingGround CoversEarth AnchoringDewatering & DrainageDrainage CompositesImpermeable LinersPermeable PavingGeocellsRock Bags

- Contact Us

What are your Temporary Works Options Using Platipus Anchor Systems?

Facebook

LinkedIn

Twitter

WhatsApp

Stabilising temporarily cut batters, slopes and excavations can be a critical work element for many Building and Civil construction projects. Whether the temporary excavation requirement is for building foundations, road or highway works, tunnelling, pipelines or trenches, there are many applications where an excavated soil or embankment needs to be cut to such a steep batter or angle of repose, that it would be naturally unstable and additional stability measures must be implemented and introduced.

With Workplace Health and Safety being a prime consideration, temporary works must be designed and detailed to facilitate a safe working space and environment for people, plant and resources for the duration of a project. This duration may only have a short-term period of a few years or quite often much less. Therefore, despite only a temporary requirement, the risk management, design and construction remains a critical element of a project.

A common temporary works solution is to implement piling measures and this can be a cantilever retaining wall driven from the ground level or surface, or a cast in-situ concrete pile. Cantilever piles can however have limitations with them relying on the piling material stiffness and bending resistance, sufficiently driven pile depth, installation time and associated specialist resources and costs. There are also potential issues and difficulties in piling removal and the environmental issues of noise pollution for the surrounding areas.

There are two main temporary works applications where Platipus Earth Anchors can play an integral part in supporting a cost effective and ‘buildable’ temporary works solution:

- Solution 1 – A tied-back piled retaining wall and support with Platipus

- Solution 2 – A full Platipus anchored embankment/slope

Solution 1

To minimise driven depths of piled walls and reduce time and money, it is common to add extra tied-back support to the top of a piled solution by way of either external props, or an anchor or soil nail driven in to the retained soil.

Generally, the anchoring solution can be either drilled and grouted soil nails or a percussion driven mechanical anchor like Platipus. Cirtex Australia have many successful case studies where the percussion driven Platipus anchor system has been chosen to hold back either the top of a sheet pile solution or concrete contiguous piled wall. Working or Design Loads can be in excess of 150kN (15 tons) per anchor system!

Solution 2

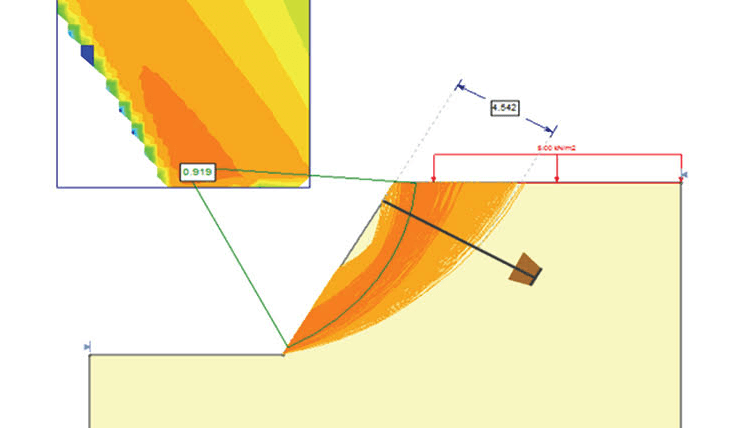

If the site constraints will allow, a slope face pattern of Platipus earth anchor systems can be used on their own with no requirement of piles which can provide a cost effective and buildable temporary slope and embankment solution.

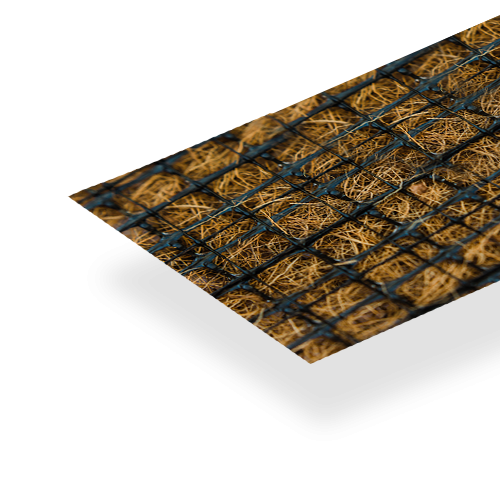

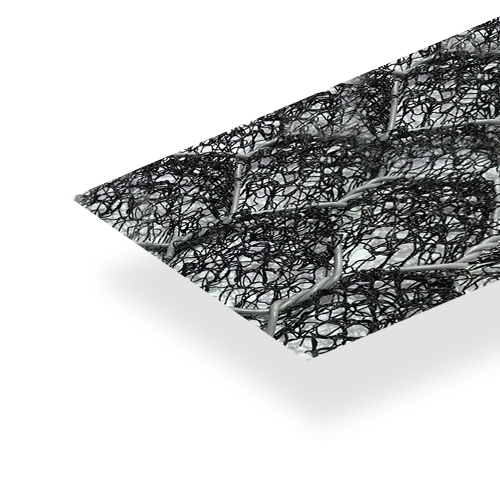

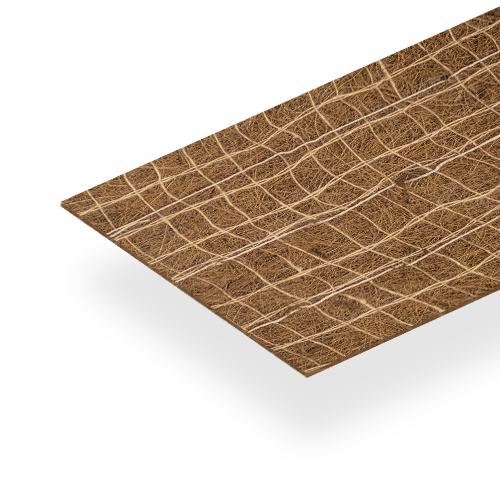

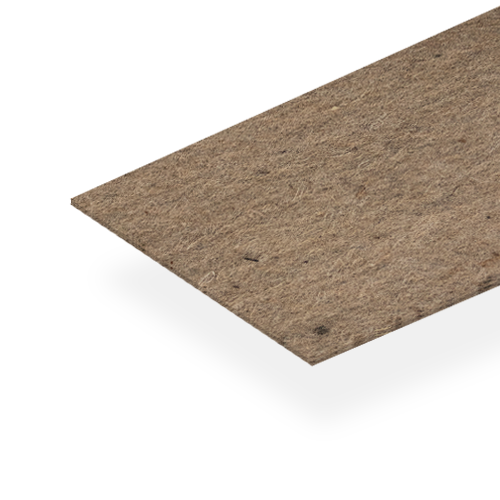

In this solution Platipus is normally used in conjunction with a temporary slope facing of a geosynthetic matting or spraycrete/shotcrete (providing bi-directional tension strength and short-term steep slope face erosion protection).

Cirtex Australia over the past two years have been involved in successfully implementing many of these types of solutions. A major case study example is the M4 West Connex motorway project in Sydney.

Major advantages of Platipus

Let’s now focus on some of the major advantages of using a Platipus percussion driven anchor system versus a drilled and grouted soil nail solution.

One of the key objectives of using Platipus is to achieve speed of installation. Temporary works solutions quite often fall along the critical path of a project and it is essential that they are constructed quickly and with minimum delay. The Platipus percussion driven earth anchor is designed to be installed quickly with locally resourced plant and equipment and by a competent contractor or sub-contractor who has been through a Platipus installer and training induction program.

One of the major advantages of the Platipus system is that the anchor head is driven and load locked deep into the stable insitu soil zone. This relies on bearing capacity theory from a dead-man anchor solution versus skin friction along a tendon bar for a traditional drilled and grouted soil nail. As soon as the Platipus anchor has been installed it is instantly load locked and load verified and ready for service.

There is no time delay or waiting around for days for grouting measures to cure and with the uncertainty of load achievement. Every single Platipus anchor is, and should be, immediately load locked and tested once driven to the required soil depths with this information immediately available for the Design Engineer to review. With this information and certainty, this allows the Engineer to quite often risk manage and incorporate reduced Factors of Safety in the design.

Let’s not forget the reduced environmental impact a ‘dry’ Platipus solution can provide. With drilling and grouting soil nails, initial drill holes are quite often required that require slurry lubrication and finally grout is pumped into the holes. Both these process’s result in potential contamination of soil and close proximity waterways which can be an environmental hazard.

The single biggest advantage that contractors have reported to us of using the Platipus system is its ‘buildability’ or ‘constructability’ and the ability or flexibility of being able to easily switch ‘on and off’ a small Platipus installation team which provides their project with a safe temporary works solution, on time and at a relatively reduced cost saving to traditional solutions.

Here’s some recent feedback and a comment from a Site Engineer on the M4 West Connex Project:

‘I have used drilled & grouted soil nails, piles and now having used Platipus, this is easily a simpler solution and will definitely consider this for future projects’

Simply….”Drive, Lock & Load with Platipus”

Learn more about our products with our design and installation videos

If you would like to discuss your temporary works requirement, contact us here